At least 6 vibration shakers are located in 3D space with integrated control and can create 6 DOF motions (3 translation DOF and 3 rotating degrees). In addition to X, Y, and Z axis motion, rotational motion, Roll, Pitch, and Yaw are also possible utilizing spherical bearings. Using electrodynamic vibration generators, IMV systems can reproduce waveforms that have components in a wide frequency range with a high degree of accuracy. System maintenance is easy. Systems comprise at least six vibration generators to act along orthogonal axes and also to generate the roll, pitch, and yaw components of vibration. A spherical bearing is used to allow rotational motion. By using electrodynamic vibration generators the system can operate over a wide frequency range with a high degree of accuracy. System maintenance is straightforward.

Features

Ride comfort evaluation system

The addition of rotational motion to a three-axis system enables 6 degree-of freedom testing, as is required for vehicle seat evaluation, for example.

specification

| Excitation direction | X axis | Y axis | Z axis |

| Rated Force (kN) | 3.9 | 7.8 | 16 |

| Maximum Disp (mmp-p) | 150 | 150 | 100 |

| Frequency Range (Hz) | 1 to 100 | ||

| Shaker Body (mm) | 1800 × 1800 | ||

| Shaker Array (unit) | 1 | 2 | 4 |

(per 1 system)

| Excitation direction | X axis | Y axis | Z axis |

| Rated Force (lbf) | 877 | 1,754 | 3,597 |

| Maximum Disp (inp-p) | 5.9 | 4.0 | 4.0 |

| Frequency Range (Hz) | 1 to 100 | ||

| Shaker Body (in) | 71 × 71 | ||

| Shaker Array (unit) | 1 | 2 | 4 |

(per 1 system)

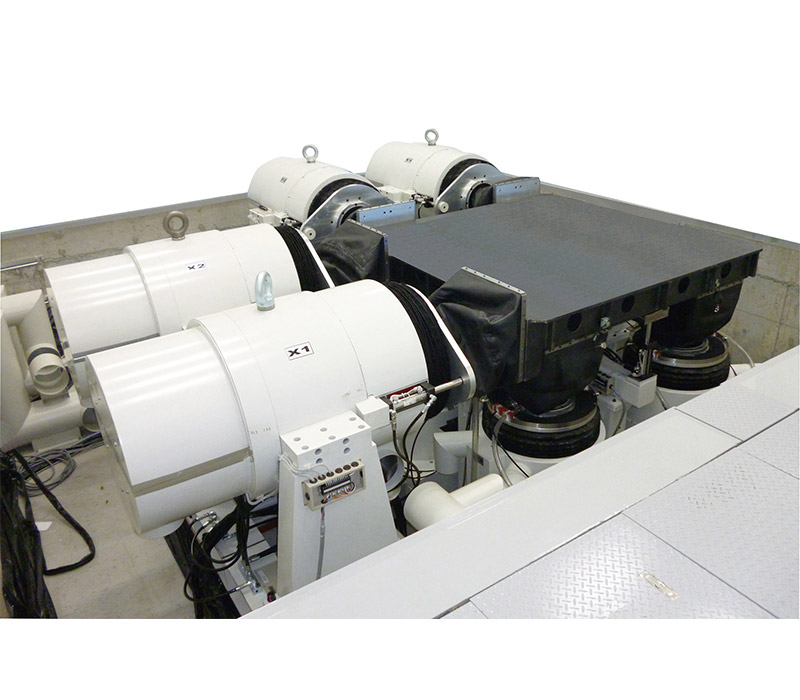

Large-scale 6 DOF vibration test system

A total of 10 vibration generators (6 vertical and 4 horizontal) and a 4000mm by 3500mm large size table allow the simultaneous 6 DOF vibration testing. This versatile platform is ideal for testing large items such as railway carriage components.

Title text example

| Excitation direction | X axis | Y axis | Z axis |

| Rated Force (kN) | 80 | 48 | 96 |

| Maximum Disp (mmp-p) | 51 | ||

| Frequency Range (Hz) | 2 to 150 | ||

| Shaker Body (mm) | 4000 × 3500 | ||

| Shaker Array (unit) | 2 | 2 | 6 |

(per 1 system)

| Excitation direction | X axis | Y axis | Z axis |

| Rated Force (lbf) | 17,985 | 10,791 | 21,582 |

| Maximum Disp (inp-p) | 2.0 | ||

| Frequency Range (Hz) | 2 to 150 | ||

| Shaker Body (in) | 157 × 138 | ||

| Shaker Array (unit) | 2 | 2 | 6 |

(per 1 system)

6 DOF simultaneous squeak and rattle test system for vehicle seats

Air-cooled vibration test system for the evaluation of squeak and rattle noise from an instrument panel or other car interior assemblies.

Specification

| Excitation direction | X axis | Y axis | Z axis |

| Rated Force (kN) | 1600 | 1600 | 3200 |

| Maximum Disp (mmp-p) | 30 | ||

| Frequency Range (Hz) | 5 to 100 | ||

| Shaker Body (mm) | 1500 × 3500 | ||

| Shaker Array (unit) | 2 | 2 | 4 |

(per 1 system)

| Excitation direction | X axis | Y axis | Z axis |

| Rated Force (lbf) | 360 | 360 | 719 |

| Maximum Disp (inp-p) | 1.2 | ||

| Frequency Range (Hz) | 5 to 100 | ||

| Shaker Body (in) | 59 × 138 | ||

| Shaker Array (unit) | 2 | 2 | 4 |

(per 1 system)