Overview

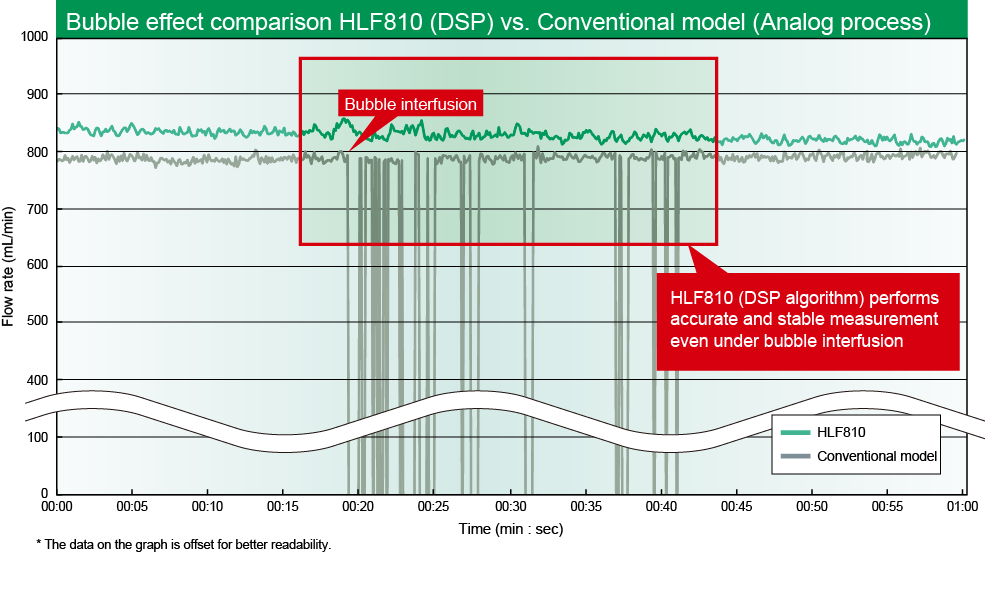

Equipped with a DSP (Digital Signal Processor), the unique signal computation ensures stable measurement.

Ultrasonic waves are used to measure the fluid velocity and calculate the flow rate from the velocity.

The flow velocity is calculated from the difference in ultrasonic wave propagation time when ultrasonic waves are emitted in the forward and reverse directions from the sensors installed upstream and downstream of the flow, and is converted to flow rate.

○Flow measurement is possible under the condition of minimum pressure loss because there is no structure in the piping.

○Wide range of flow velocity can be measured from low to high velocity.

Special feature

●Equipped with a DSP (Digital Signal Processor), the unique signal computaion ensures stable measurement.

● Two different sizes of sensors can be connected to the same converter.

Up to two sensors can be connected to one converter, which saves space and offers excellent cost performance for equipment that measures flow rates at multiple locations. In addition to flow measurement of different fluids, sensors in different sizes can also be connected.

●Equipped with VFD display

The VFD (fluorescent display tube) display provides excellent visibility. HLF820 only.

●High-temperature chemical flow measurement

Compatible with recent diversification of chemical and fluid temperatures. All liquid contact surfaces are made of NEW PFA for superior chemical resistance. Our self-developed transducers enable flow measurement at high temperature of up to to 200°C (K type).

*04 type is available up to 180°C.

●Easy wiring work by detachable cable

Since the wiring cable from the sensor unit is detachable, wiring can be done smoothly after installation in the device. The cable length can be selected from 5m and 7m.

●RS-485 communication enables remote monitoring with a PC

RS-485 communication is standard-equipped. Parameter setting and reading out of measurement data can be done on a PC by using the management software (HLF800 Monitor), enabling remote flow monitoring.

Applications

・Measuring the flow of deionized water or ultrapure water for semiconductor manufacturing processes

・Measuring the flow of highly corrosive chemical liquid used in chemical treatment processes

・Measuring the flow of slurry liquids for CMP (Chemical Mechanical Polishing) process

Specifications

Sensor type

Converter

| Model | HLF810 | HLF820 | |

| Measurement method | Ultrasonic wave propagation time difference method | ||

| Data update cycle | 0.01 seconds | ||

| Power | Voltage | DC24V ±10%(21.6~26.4V) | |

| Power consumption | Approx. 4W | Approx. 5W | |

| Display | – | VFD (fluorescent tube) 16 characters x 2 lines | |

| Digital input | Open collector input or no-voltage contact input 2 points Select from totalizer reset or zero point adjustment |

||

| Output | 4-20mA current output | 2 points Resolution: 12bit (Max. load resistance 600Ω) |

|

| Digital output | Open collector output (MAX35V/0.1A) 2 points Select from comparison, integrated pulse, instantaneous frequency, and error output |

||

| Interface | RS-485 (MODBUS protocol, RTU mode) 32 units can be concatenated (addresses 1-32) Communication speed: 9600, 19200, 38400, 57600 bps |

||

| Case Material | ABS | ||

| Ambient operating temperature | 0 to 50°C (no condensation) | ||

| Weight | 130g | 230g | |

| Installation method | DIN Rail | Panel | |

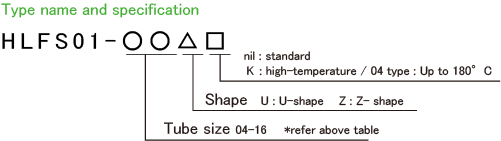

Sensor

| Model | HLFS01-04 | HLFS01-06 | |||

| Object of measurement | Ultrapure water / Pure water / Chemical solution | ||||

| Measuring flow rate range | 0~2L/min | 0~6L/min | |||

| Connecting Tube Size | 1/4″ | 3/8″ | |||

| Accuracy*1 | Measured flow rate | 0 to less than 800 mL/min | 800~2000mL/min | 0 to less than 2000 mL/min | 2000~6000mL/min |

| Flow rate accuracy | ±8mL/min | ±1% R.D. | ±20mL/min | ±1% R.D. | |

| Withstanding pressure | 0.5MPa (0~90℃) / 0.2MPa (90~200℃) | ||||

| Fluid temperature | Standard | 0~90℃ | |||

| High temperature | 0~180℃ | 0~200℃ | |||

| Ambient operating temperature | 0~80℃ | ||||

| Wetted part material | NEW PFA | ||||

| Weight | 90g | 110g | |||

| Intrinsic Loss Coefficient | 3.7863 | 0.0937 | |||

| Model | HLFS01-08 | HLFS01-12 | |||

| Object of measurement | Ultrapure water / Pure water / Chemical solution | ||||

| Measuring flow rate range | 0~20L/min | 0~50L/min | |||

| Connecting Tube Size | 1/2″ | 3/4″ | |||

| Accuracy*1 | Measured flow rate | 0 to less than 4.3L/min | 4.3~20L/min | 0 to less than 11.8L/min | 11.8~50L/min |

| Flow rate accuracy | ±43mL/min | ±1% R.D. | ±118mL/min | ±1% R.D. | |

| Withstanding pressure | 0.5MPa (0~90℃) / 0.2MPa (90~200℃) | ||||

| Fluid temperature | Standard | 0~90℃ | |||

| High temperature | 0~200℃ | ||||

| Ambient operating temperature | 0~80℃ | ||||

| Wetted part material | NEW PFA | ||||

| Weight | 130g | 160g | |||

| Intrinsic Loss Coefficient | 0.1146 | 0.0.0138 | |||

| Model | HLFS01-16 | ||||

| Object of measurement | Ultrapure water / Pure water / Chemical solution | ||||

| Measuring flow rate range | 1″ | ||||

| Connecting Tube Size | 1/2″ | ||||

| Accuracy*1 | Measured flow rate | 0 to less than 20 L/min | 20~80L/min | ||

| Flow rate accuracy | ±200mL/min | ±1% R.D. | |||

| Withstanding pressure | 0.5MPa (0~60℃) / 0.2MPa (60~200℃) | ||||

| Fluid temperature | Standard | – | |||

| High temperature | 0~200℃ | ||||

| Ambient operating temperature | 0~80℃ | ||||

| Wetted part material | NEW PFA | ||||

| Weight | 220g | ||||

| Intrinsic Loss Coefficient | 0.0033 | ||||

*1 Pure water at 20°C Repeat accuracy in our inspection environment

Intrinsic loss coefficient A of each sensor (pure water at 20°C)

⊿P=AQ2 ⊿P: Pressure loss [KPa] A: Intrinsic loss coefficient Q: Flow rate [L/min]

Converter-sensor connection cable

| Model | HLFS01 cable 5m | HLFS01 cable 7m | ||

| Material | ETFE | |||

| Length | 5m | 7m | ||

| Weight | 150g | 210g | ||