APPLICATION

Knowing processing characteristics of polymer materials such as thermoplastic resins, thermosetting resins

and elastomers is very important for cost reduction and quality control.

In developing of new materials in addition to knowing the processing characteristics it is also important to find

out through simulation whether the material can be molded or not and determine appropriate processing

conditions.

This Labo Plastomill perform these tests on small quantities of samples, mainly the following tests.

– Processing characteristics evaluation test by small mixer (30 to 90cm

3

)

– Simulation and other evaluation tests by small extruder (ø20mm)

The Labo Plastomill is a practical testing machine (shear force acts) which provides many reliable information

necessary for molding process and is already being used in numerous industries and related fields for this

purpose.

1. BASE UNIT (Drive Unit)

The computer controls the machine and performs data processing of various characteristic values taking torque, resin temperature and pressure as parameters.

All controls and data processing are performed by computer. By recalling already registered testing conditions, filling sample and then starting the machine, waveform graphs of torque, pressure, resin temperature and energy, etc. are displayed and measurement proceeds according to the testing conditions.

In mixer test, programmed control operation of temperature and revolution is also possible.

In addition to allowing enlargement and reduction of waveform graph, data analysis processes the function of computing characteristic values of various patterns separately for each mode and

Characteristic value points can be arbitrarily specified form waveform graph and in mixer test automatic detection by automatic calculation function is also possible.

(Mixer shown is option)

| Model | 3S150 | 10S100 | 3S500 |

| Operation & data processing | Personal Computer | ||

| Max. torque | 300Nm | 1000Nm | 300N.m |

| Speed range | 0.1 to 150rpm | 0.1 to 100rpm | 0.1 to 500rpm |

| Motor power | 3.5kW | 5.5kW | 15kW |

| Torque detection | Load cell | Torque meter | |

| Torque measurement accuracy | ±0.1% within FS | ||

| Pressure & temperature

amplifier |

4 each of pressure & temperature | ||

| Temperature controller | 6 channel | ||

| Safety guards | Torque limiter, Pressure limiter, Temperature limiter,

Heater disconnection alarm, Emergency stop switch, Coupling safety cover, Earth leakage breaker etc. |

||

| Power supply

(Base unit only. Power supply for each measuring heads are required as well) |

Three-phase, AC200V, 60A | Three-phase, AC200V, 100A | |

| Dimensions (Base unit only) | W525 x D660 x H950mm | ||

| Net weight (Base unit only) | 3S150: Approx. 215kg 10S100: Approx. 235kg 3S500: Approx. 285kg | ||

2. MIXERS

Mixer’s heating block, that is the sample kneading part of Labo Plastomill, contains 2 kneading blades rotating in same direction or two kneading blades rotating in different directions and resin temperature sensors.

Mixing and kneading of sample filled in the mixer proceeds as it receives heat and shear from the blade and its state of melting, dispersion, distribution, steadiness, deterioration, curing reaction, cross-linking, heat generation, etc. changes in various forms according to the characteristics of the sample.

Since these changes in state appear as change in the torque acting mechanically on the blade, the behavior of torque and resin temperature are continuously detected and displayed on the monitor.

In mixer test, processing characteristics such as gelling characteristic, dynamic thermal stability, curing characteristic, dispersion characteristic, etc. can be determined as index.

Moreover, since mechanically provided energy (MH/m3) consumed per unit volume is calculated, information regarding mixer scale up and comparison among samples can also be obtained. The middle size mixer (100cm3 or larger) is generally used to collect large quantity of kneaded substances as secondary sample in addition to conducting above-mentioned tests.

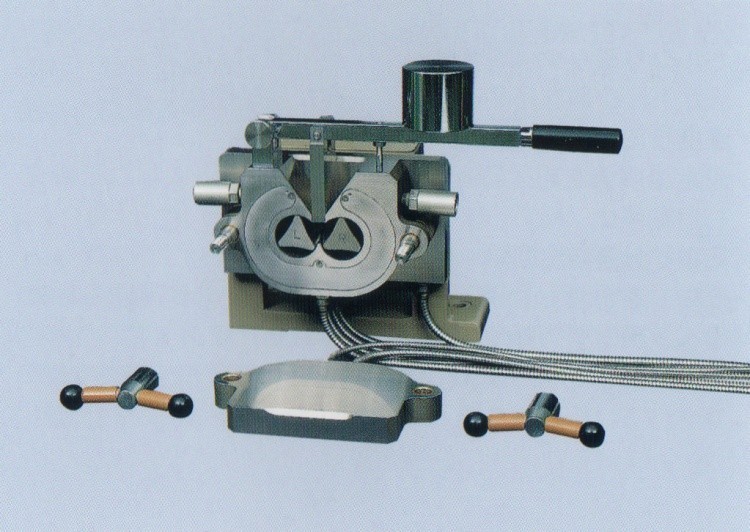

Mixers for Thermosetting Resins (Roller & Delta type)

| Model | R30 / R30H | D30 / D30H |

| Chamber Capacity (Approx.) | 30cm3 | |

| Main Application | Thermosetting resins | |

| Shear Strength | High | |

| Rotation Speed | Same speed of motor rotation | |

| Blade Revolution Ratio | 2 : 3 | |

| Sample Insertion

System |

Lever type | |

| Heating System | Electric | |

| Max. Temperature | 250°C (R30H: 400°C) | 250°C (D30H: 400°C) |

| Max. Permissible

Torque |

200N.m | 300N.m |

| Cooling Device (Air) | Option | |

| Power Supply | Single-phase,

AC200V, 3.2A (R30H: 6.3A) |

Single-phase,

AC200V, 3.2A (D30H: 6.3A |

Mixers for Thermoplastic Resins (Roller type etc.)

Features of Roller mixer (R60)

- Capacity: Approx. 60cm3

- Blade rotation ratio: 2:3 (Left : Right) Rotating different direction

- Electric heating

- Cooling by compressed air (Option)

- 3 heating zones :

- Temperature range up to 250°C (400°C optional)

- Exchangeable rotor blades

-Roller rotor blade (R60B)

-Cam rotor blade (C90B)

-Sigma rotor blade (S90B)

-Banbury rotor blade (B60B)

| Model | R60 / R60H | C90 / C90H | S90 / S90H |

| Chamber Capacity (Approx.) | 60cm3 | 90cm3 | |

| Main Application | Thermoplastics | ||

| Shear Strength | High | Middle | Low |

| Rotation Speed | Same speed of motor rotation | ||

| Blade Revolution Ratio | 2 : 3 | ||

| Heating System | Electric | ||

| Max. Temperature | 250°C (R60H: 400°C) | 250°C (C90H: 400°C) | 250°C (S90H: 400°C) |

| Max. Permissible

Torque |

200N.m | 300N.m | |

| Cooling Device (Air) | Option | ||

| Power Supply | Single-phase, AC200V, 3.7A (R60H: 8.7A) | Single-phase, AC200V, 3.7A (C90H: 8.7A) | Single-phase, AC200V, 3.7A (S90H: 8.7A) |

| Model | R100 / R100H | R200 / R200H | R500 / R500H |

| Chamber Capacity (Approx.) | 100cm3 | 200cm3 | 500cm3 |

| Blade Shape | Roller type | ||

| Main Application | Thermoplastics | ||

| Shear Strength | High | ||

| Rotation Speed | Same speed of motor rotation | ||

| Blade Revolution Ratio | 2 : 3 | ||

| Heating System | Electric | ||

| Max. Temperature | 250°C (R100H: 400°C) | 250°C (R200H: 400°C) | 250°C (R500H: 400°C) |

| Max. Permissible

Torque |

300N.m | 750N.m | 1000N.m |

| Cooling Device (Air) | Option | Standard | |

| Power Supply | Single-phase, AC200V, 4.1A

(R100H: 8.7A) |

Single-phase, AC200V, 10.5A

(R200H: 16A) |

Single-phase, AC200V, 15.3A

(R500H: 19.7A) |

Mixers for Thermoplastic Resins (Segment type)

Features of Segment Mixer (KF6/KF6V)

- Heavy kneading test by means of intermeshing type co-rotary

- Arbitrary adjustment of heavy/light kneading by changing disk phase composition of

- Disk phase of blade is possible to change

| Low shearing disk phase | High shearing disk phase |

| Max share rate: 450 s-1 Dispersion: Low Distribution: High | Max share rate: 1173 s-1 Dispersion: High Distribution: Low |

| Model | KF6 / KF6V | KF15V | KF70V2 | |

| Disk model | Disk I (option) and

Disk II (standard) Please select Disk I or Disk II |

Disk I (standard) | ||

| Chamber capacity | Disk I: Approx. 6cm3

Disk II: Approx. 5cm3 |

Disk I: Approx. 15cm3

Disk II: Approx. 14cm3 |

Disk I: Approx. 70cm3 | |

| Shape of blade | Disk | |||

| Chip clearance | Disk I: 0.75mm Disk II: 0.3mm | Disk I: 0.88mm Disk II: 0.3mm | Disk I: 0.4mm | |

| Rotation speed | Triple speed (3 times of motor rotation speed) | Double speed (2 times of motor rotation speed) | ||

| Blade revolution ratio | 1:1 | |||

| Sample insertion system | Rack and pinion type lever (KF6: Lever type) | |||

| Heating system | Electric | |||

| Max. temperature | 350°C | |||

| Main application | Thermoplastic (Very high shear) | |||

| Max. permissible torque | 40N.m | 100N.m | 300N.m | |

| Cooling device (Equipped as standard) | Compressed air cooling

(Water cooling is possible under 100°C) |

|||

| Power supply | Single-phase,

AC100V, 15A |

Single-phase,

AC200V, 12.9A |

Single-phase,

AC200V, 14.3A |

|

Mixers for Elastomers (Banbury type)

Electric heating type

| Model | B75 | B250 / B250H | B600 / B600H |

| Chamber Capacity (Approx.) | 75cm3 | 250cm3 | 600cm3 |

| Blade Shape | Banbury type | ||

| Main Application | Elastomers | ||

| Blade Revolution Ratio | 7 : 8 | 8 : 9 | 7 : 8 |

| Sample Insertion

System |

Lever type

(Air cylinder: option) |

Air cylinder | |

| Heating System | Electric | ||

| Max. Temperature | 250°C | 250°C (B250H: 400°C) | 250°C (B600H: 400°C) |

| Max. Permissible

Torque |

300N.m | 750N.m | 1000N.m |

| Cooling Device (Air) | Option | Standard | |

| Power Supply | Single-phase, AC200V, 4A | Single-phase, AC200V, 10.5A (B250H: 16A) | Single-phase, AC200V, 15.3A (B600H: 19.7A) |

Oil heating type

| Model | BR250 | BR600 | |

| Chamber Capacity (Approx.) | 250 cm3 | 600cm3 | |

| Blade Shape | Banbury type | ||

| Main Application | Elastomers | ||

| Blade Revolution Ratio | 8 : 9 | 7 : 8 | |

| Sample Insertion

System |

Air cylinder | ||

| Heating System | Oil heating | ||

| Max. Temperature | 180°C | ||

| Max. Permissible Torque | 750N.m | 1000N.m | |

| Cooling Device (Air) | N/A | ||

| Power Supply | Single-phase, AC200V, 28A

(Oil circulation bath, model OP) |

||

Mixer for PVC Dry blend (Planetary type)

| Model | P600F |

| Chamber Capacity (Approx.) | 600cm3 |

| Main Application | PVC dry blend |

| Heating System | Electric |

| Max. Temperature | 150°C |

| Max. Permissible Torque | 30N.m |

| Cooling Device (Air) | N/A |

| Power Supply | Single-phase, AC200V, 4A |

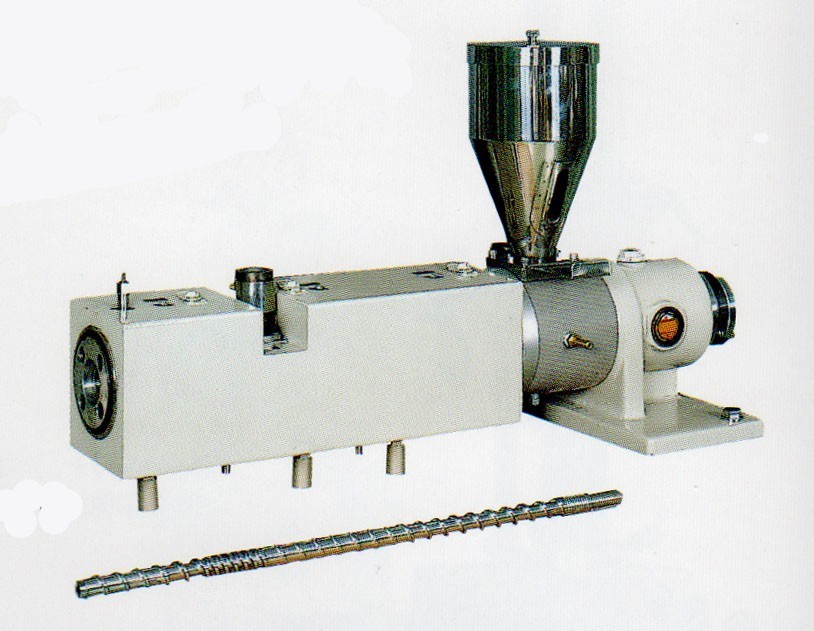

3. EXTRUDERS

In small size extruder test of Labo Plastomill, in addition to detecting torque, the pressure and temperature (maximum 4 points each) are also continuously detected during molding by installing resin temperature sensor and resin pressure sensor in the cylinder or die and the values are displayed on the monitor.

Various kinds of molding dies and take-off devices are also available, allowing you to determine molding conditions by simulating and obtain various information such as pressure, temperature, torque, specific energy (MJ/m3) and extrusion amount at each rpm (each shear rate) in addition to detecting mold status such as extrusion mold product’s fish eye, dispersion, transparency and gloss by using a small quantity of sample.

Single Screw Extruders for Elastomers

| Model | D2010 | D2015 |

| Screw Diameter | 20mm | |

| L/D | 10 | 15 |

| Max. Temperature | 250°C | |

| Heating System | Electric | |

| Heating Zone (Cylinder) | 1 | 2 |

| Air cooling (Cylinder) | Possible | |

| Vent Port | N/A | |

| Pressure/Temperature Measurement Hole | 2 | |

| Standard Die Head | Garvey die | |

| Standard Screw | Full flight screw (CR=1.6) | |

| Standard Hopper | Roll feeder | |

| Max. Permissible Torque | 200N.m | |

| Power Supply | Single-phase, AC200V, 3.2A | Single-phase, AC100V, 3.2A |

Single Screw Extruders for Thermoplastics

| Model | D2020 | D2025 |

| Screw Diameter | 20mm | |

| L/D | 20 | 25 |

| Max. Temperature | 350°C | |

| Heating System | Electric | |

| Heating Zone (Cylinder) | 3 | |

| Air cooling (Cylinder) | Possible | |

| Vent Port | N/A | 1 |

| Pressure/Temperature Measurement Hole | 4 | |

| Standard Die Head | Strand die (Ø3mm x 1) | |

| Standard Screw | Full flight screw (CR:2.5) | Vent screw (CR:No.1=2.5, No.2=3.0)

(Full flight screw is available as option) |

| Standard Hopper | Steel hopper | |

| Max. Permissible Torque | 200N.m | |

| Power Supply | Single-phase, AC200V, 9.0A | Single-phase, AC200V, 9.8A |

| Dimensions | W230 x L830 x H450mm | W230 x L930 x H450mm |

Single screw extruder for thermoplastics (for Labo Plastomill Micro)

| Model | D1220 |

| Screw Diameter | 12mm |

| L/D | 20 |

| Max. Temperature | 350°C |

| Heating System | Electric |

| Heating Zone (Cylinder) | 2 |

| Air cooling (Cylinder) | Possible |

| Vent Port | N/A |

| Pressure Measurement Hole | 1 |

| Standard Die Head | Strand die (Ø2.5mm x 1) |

| Standard Screw | Full flight screw (CR=2.5) |

| Standard Hopper | Steel hopper |

| Max. Permissible Torque | |

| Power Supply | Single-phase, AC100V, 12A |