Overview

The GW type distributing valve provides a small-scale, low-cost centralized lubricating system. Various lubrication pumps (grease guns, hand pumps, compact air-driven pumps) can be connected to the lubricating port (grease nipple R1/8 button head type) to reliably perform metered supply of lubricant to each lubricating point.

Installing this distributing valve to match the number of lubricating ports on the machine to be lubricated and performing lubrication periodically is advantageous in many ways. That is, lubrication can be performed at appropriate amounts in a short time, lubrication is not missed, and simple centralized lubrication is possible without the need for extra large-scale facilities like a dual line system, and costs can be reduced.

Features

• Suited to Small-Scale Centralized Lubrication Systems

Centralized lubrication can be easily performed with handy equipment.

• Accurate Lubrication Amount Assured

Metered lubrication can be accurately performed by freely adjusting the lubrication amount. Missed lubrication can also be prevented.

• Number of Lubrication Points Can Be Easily Adjusted

The number of lubrication points can be easily increased or decreased by simply attaching and removing a plug.

• Solid, Outstanding Durability

Specifications

| Model | GW-54H | GW-58H | |

| Max. operating pressure (MPa) | 21 | ||

| Pressure resistance (MPa) | 31.5 | ||

| Discharge quantity (cm3/stroke) | MAX | 5.0 | |

| MIN | 1.2 | ||

| Min. operating pressure (MPa) | 1.2 | ||

| Adjustment amount per rotation of adjusting screw (cm3) | 0.15 | ||

| Number of discharging ports (port No.) | 4 (1 to 4 port) | 8 (5 to 8 port) | |

| Grease Used | NLGI consistency #0 to #2 for centralized lubrication | ||

| Accessories (for installation) | M8 x 75 Cross recessed pan head screw, spring washer, hexagon nut | ||

| Weight (kg) | 2.7 | 4.7 | |

Note) For the grease used in a progressive system, select in the range “NLGI consistency #0 to #1 for centralized lubrication.” Choose grease used in the progressive system in the range of “NLGI consistency number #0 to #1” for centralized lubrication.

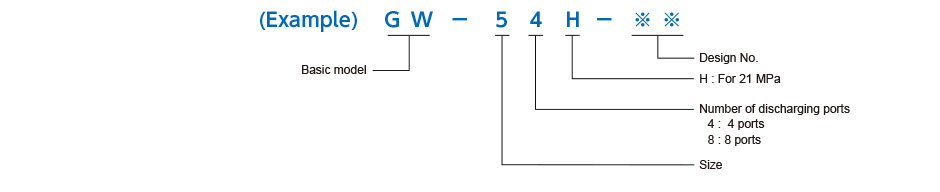

Explanation of Model Symbols