One of Bonfiglioli’s Leak Test & Quality Inspection systems, which detects leakage in pill blister and pouch packaging, was quickly becoming inefficient and outdated. Blue ink was put into the holding chamber and then depressurized. The ink would then seep into any crevices within the blister cavities, identifying faulty product. However, replacing the ink was wasting time and money.

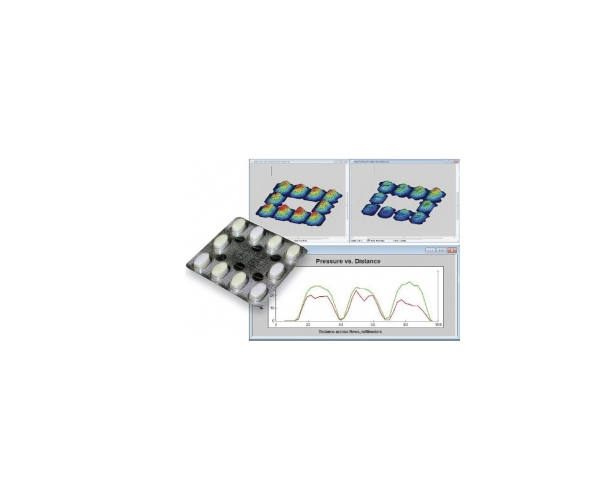

Instead of using ink, Bonfiglioli integrated a Tekscan tactile pressure sensor into their test machinery and developed their BenchTop Lid Deflection Leak Testing Machine®. The sensor is embedded in the lid of the machine, and after the lid is closed and the chamber is sealed, the machine creates a vacuum and depressurizes the chamber. As the blister cavities within the package swell, the sensor measures the pressure distribution of each cavity. The resulting data is shown on the machine’s display, using a software API. As a result, cavities with low pressure can be identified as failure points where air is leaking from the blister. This new process saved its customers time and money, allowing Bonfiglioli to be more competitive.

Incorporating a Tekscan tactile pressure sensor into their product, which is reusable, lasts long, and provides valuable information, proved successful for Bonfiglioli. Tekscan sensors are flexible and customizable, depending on the application needs of our customers. They continue to be used in new and innovative ways in an ever-expanding array of important applications.