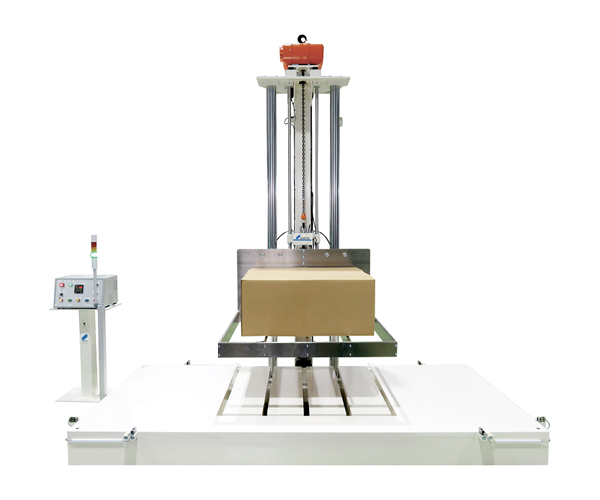

Vertical Drop Tester for Heavy Packaging

DT-300 can aid in providing basic test for package specifications including cushioned package design, selection in packaging materials, fragility of packaged contents, standard test of packaged freights (surfaces only), etc. It can be performed efficiently with a high level of accuracy.

Features

- Free drop in precise posture

- The table which carried a specimen carries out fall operation holding the product, and free-drop for a specimen in precise posture.

- Controll drop height

- The drop height of packaged cargo is performed by digital set-up of a control device, and risen to specification height by motor-brock, and is separated by drop switch after holding a position in air brake.

- Anti-rebound of drop table

- When the specimen table is dropping to base, the shock absorber and the air brake will stop the table rebound as the table will be stored in the groove of base and be kept from bounding on the base upper surface.

- Taiking care for safty use

- The drop operation cannot be activated when the the specimen table does not set to drop height position.

In order to prevent unprepared drop operation, drop test is operated by two push-button switches.

As accessories, equip the base with Photoelectronic Sensor, it will stop drop test when it detects worker’s leg and something on the base.

Applied Standard

- ISO 2248

- ASTM D5276

- JIS Z 0200

- JIS Z 0202

Applications

Heavy packaged cargo of free drop test from a minimum of 1 cm to 100 cm is available.

Specification

| Model | DT-300 |

|---|---|

| Specimen max size (mm) | W1600 × D1200 × H1500 |

| Specimen max weight (kg) | 300 |

| Drop height range (mm) | 50 ~ 1000 |

| Drop attitude | corner and edge drop by specialized jig |

| Drop height setting | Digital setup by a controller |

| Brake of lifting table | Shock absorber and Counter-pressure brake |

| Size (mm) | W1700 × D1800 × H2600 |

| Capacity (kg) | about 3600 |

| Power supply | AC200V, 3 phasese, 7A |

| Air pressure (MPa) | 0.7 or more |