Popular Model of Drop Test for Packaging

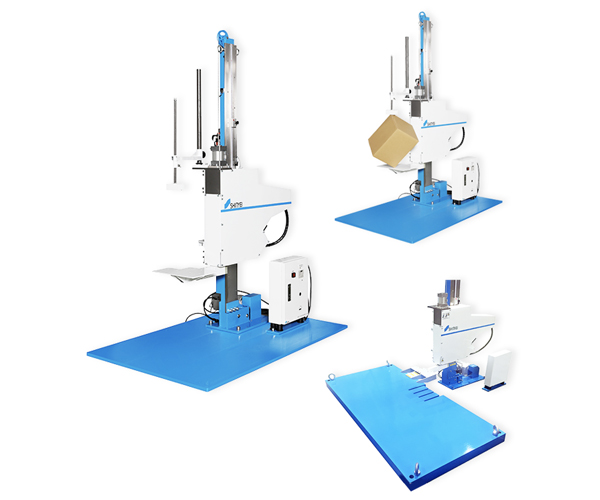

This is a drop tester for packaging that has an air-driven cylinder and tension spring that functions by releasing the sample faster than the free falling speed, aiding the free falling of test sample. This system allows for a dramatic improvement in the falling posture of the test sample and a faster testing cycle. You can conduct accurate drop test using this model.

Features

- Specialized for packaged freight

- Wide range of test samples

- High Reproducibility

- Easy Maintenance for Long Term Usage

- Easy-to-Use Test Settings

- Simple Setting by Simple Construction

Applied Standard

- ISO 2248

- ASTM D5276

- IEC 60068-2-31

Applications

- Free drop test of packaged freights.

- Fragility test of products.

Option for DTS

- Support Jig for corner/edge drop

- Basement for drop test at low height

- Safety installations

(Safety fence, Mat-switch, Photoelectric Sensor) - Shock acceleration measuring device Shock Manager(Model:SM-500)

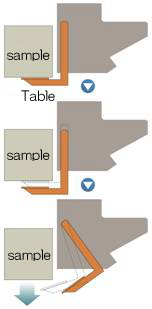

Mechanism diagram

Specification

| Model | DTS-50 | DTS-80 |

|---|---|---|

| Specimen max weight(kg) | 50 | 80 |

| Specimen max size (mm) | W900 × D510 × H900 | W900 × D575 × H900 |

| Drop height range (mm) ※ | 200 ~ 1200 | 200 ~ 1800 |

| Operation with drop test | High-speed vertical & rotational motion. | |

| Capacity (kg) | 300 | 420 |

| Size (mm) | W920 × D1480 × H1975 | W1000 × D1750 × H2583 |

| Power supply | AC200V, 3 phasese, 5A | |

| Air pressure (MPa) | 0.6 or more | 0.7 or more |

※ Depends on standard specification (Maximum drop height can be customed)