Product Features

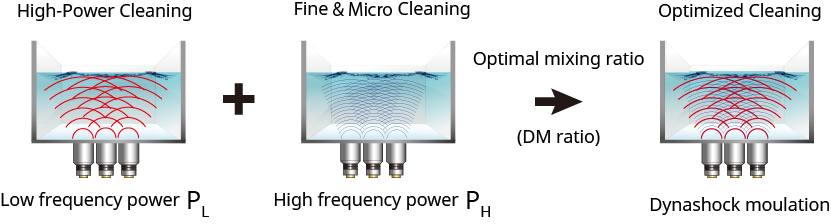

Our unique “Dyna-Shock Modulation (DM)” method by full digital technology enables full-range cleaning, from gentle to powerful, and provides the optimum cleaning effect for each application.

What is the Dyna Shock Modulation (DM) ?

The DM (DYNASHOCK MODULATION) is an oscillation method to obtain optimal cleaning effect for both gentle and powerful cleaning by controlling the ratio (modulation) of ultrasonic power generated simultaneously by two frequencies from the same transducer while the total output power remains constant.

By adjusting the ultrasonic power ratio between a low-frequency component suitable for powerful cleaning and a high-frequency component suitable for precision cleaning with low damage, optimal cleaning effects can be obtained according to the cleaning purpose, from powerful cleaning to precision cleaning.

In the WDX series, the ultrasonic power ratio of the two frequencies is called DM modulation. When the ultrasonic power of the low-frequency component is PL and the ultrasonic power of the high-frequency component is PH, it is defined as DM modulation degree = PL÷PH.

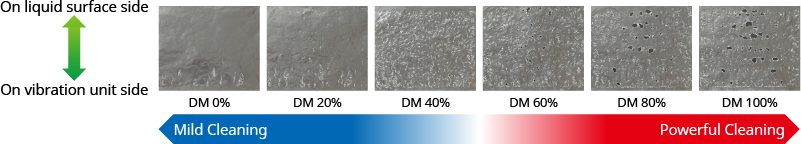

■Comparison of DM modulation and aluminum foil erosion

(Irradiated at constant ultrasonic output of 600W)

Special feature

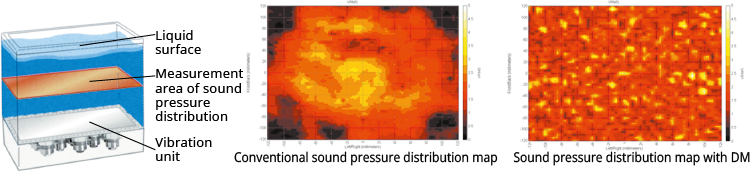

◆Dyna-shock modulation (DM) method reduces cleaning irregularities and damage, and allows selection of cleaning power according to the application, from precision cleaning to hard cleaning of metal processed parts, etc.

◆The selection of DM modulation generates uniform ultrasonic waves with high sound pressure throughout the entire tank. This allows for even and uniform cleaning.

◆Digital control system realizes various functions.

・Realization of optimal cleaning

Stable ultrasonic cleaning is realized by optimal frequency control and ultrasonic output control.

・Improved maintainability

Auto-tuning function eliminates the need to adjust the generator when replacing the transducer unit.

・Wide range of power supply input

Supports power input of 200 VAC to 240 VAC ±10%.

・Monitoring function

Output power can be monitored at the front panel display.

・Error diagnosis function

When an abnormality occurs, an error message indicating the cause of the abnormality is displayed for quick corrective action.

・Sweep function

By adding a sweep function to the DM system, more uniform ultrasonic cleaning is possible.

Applications

Metal and Machined Parts Cleaning Precision Machined Parts Cleaning

Printed circuit board cleaning Solar cell parts cleaning

Cleaning of HDD parts cleaning Cleaning of LCD parts cleaning Cleaning of Optical parts cleaning

Semiconductor parts cleaning Food utensils and medical equipment cleaning

Specifications

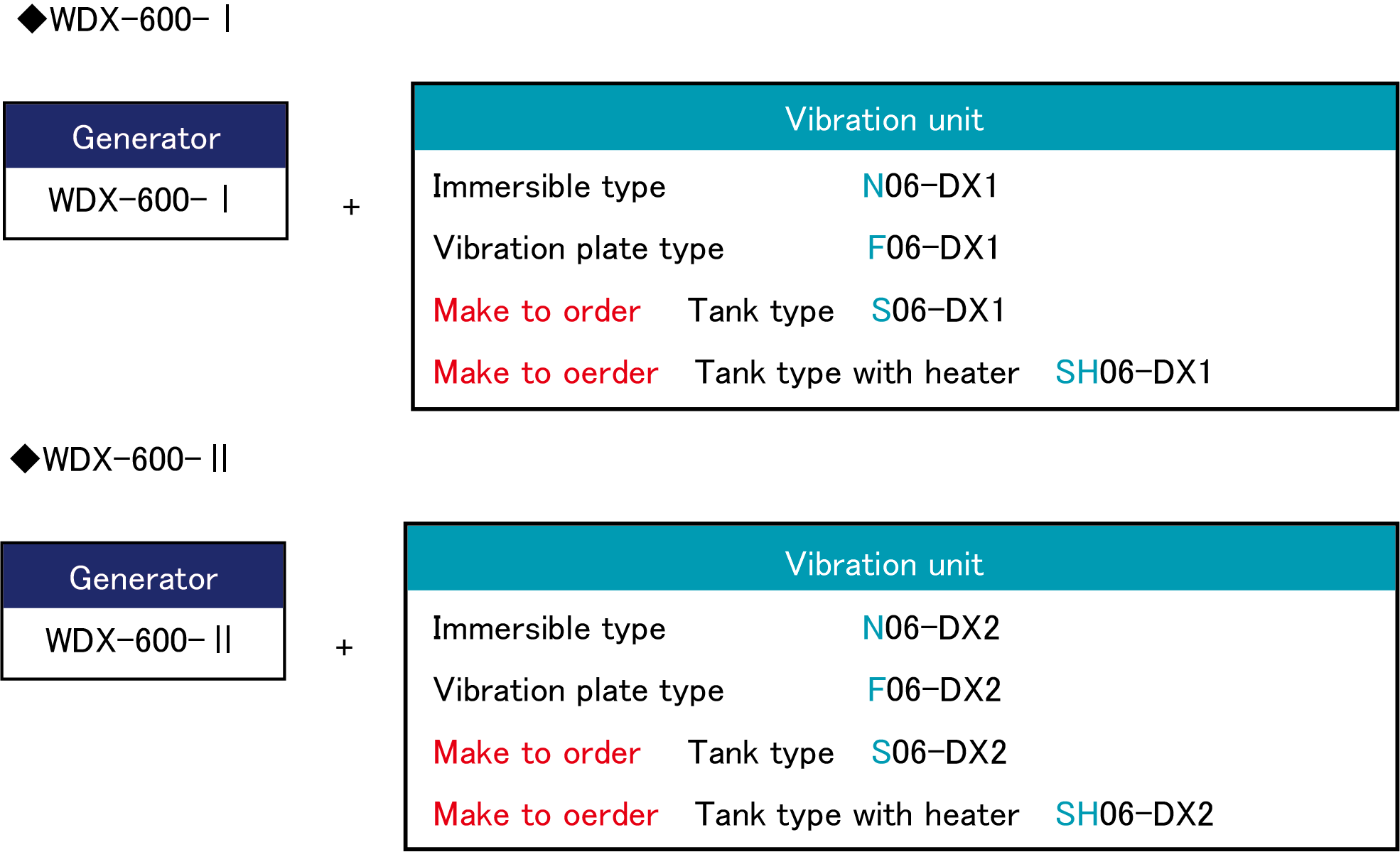

[Example of combination]

Generator

| Model | WDX-600-I | WDX-1200-I | WDX-600-Ⅱ | |

| Rated output | 600W | 1200W | 600W | |

| Nominal oscillation frequency | 28kHz、75kHz | 40kHz、120kHz | ||

| Power input | AC200V〜240V Single phase 50/60Hz 1200VA |

AC200V〜240V Single phase 50/60Hz 2400VA |

AC200V〜240V Single phase 50/60Hz 1450VA |

|

| External Dimensions WxDxHmm |

330×462×148mm (Excluding protruding parts, including rubber feet) |

|||

| Weight | 11kg | 12kg | 11kg | |

●I/O interface

Remote function: Ultrasonic oscillation ON/OFF (contact input)

Output function: Alarm output in case of abnormality (relay contact output: open in case of abnormality)

●Output variable range: 0 to 100%.

●Display function: Output power (W), DM modulation (%), error messages

●Ambient operating environment: temperature: 5 to 40°C, humidity: 5 to 80% (with no condensation)

●Power cable length: 3.5 m

●Optional accessory: crystal oscillator terminal block

Go to Options for ultrasonic cleaners

Vibrator Unit

*Transducer unit can be manufactured with custom specifications, sch as decompression, upon request.

N Type | immersible type N type

| Model | N06-DX1 | N12-DX1 | N06-DX2 |

| Generator Model No. | WDX-600-I | WDX-1200-I | WDX-600-Ⅱ |

| Maximum allowable input | 600W | 1200W | 600W |

| Nominal oscillation frequency | 28kHz、75kHz | 40kHz、120kHz | |

| Effective cleaning area | 350x200 | 420x300 | 350x200 |

| Dimensions WxDxHmm (Excluding protruding parts) |

350x200x100 | 420x300x100 | 350x200x75 |

| Material | Case: SUS304 (SUS316L available upon special order) | ||

| Weight | 14kg | 18kg | 11kg |

●Liquid temperature range: 5 to 80°C

●Transducer: Bolt-clamped Langevin type transducer

●Transducer cable length: 2.5m (blade part 2m) + output cord 3.5m

F Type | Vibration plate type

| Model |

F06-DX1 | F12-DX1 | F06-DX2 |

| Generator Model No. | WDX-600-I | WDX-1200-I | WDX-600-Ⅱ |

| Maximum allowable input | 600W | 1200W | 600W |

| Nominal oscillation frequency | 28kHz、75kHz | 40kHz、120kHz | |

| Effective cleaning area | 350x200 | 420x300 | 350x200 |

| Dimensions WxDxHmm (Excluding protruding parts) |

390x240x83 t=3㎜ |

460x340x83 t=3㎜ |

390x240x57 t=3㎜ |

| Material | Plate: SUS304 (SUS316L available by special order) Packing: EPDM t=3mm (Viton, etc. available by special order) |

||

| Weight | 10kg | 16kg | 8kg |

●Liquid temperature range: 5 to 100°C

●Transducer: Bolt-clamped Langevin type transducer

●Transducer cable length: 3.5m + output cord 3.5m

S Type | Tank type made to order

| Model | S06-DX1 | S12-DX1 | S06-DX2 | |

| Generator Model No. | WDX-600-I | WDX-1200-I | WDX-600-Ⅱ | |

| Maximum allowable input | 600W | 1200W | 600W | |

| Nominal oscillation frequency | 28kHz、75kHz | 40kHz、120kHz | ||

| Effective cleaning area | 370×250 | 500x300 | 370×250 | |

| DimensionsWxDxHmm (Excluding protruding parts) |

Externals | 422x302x405(Including rubber feet) | 550x350x402(Including rubber feet) | 422x302x405(Including rubber feet) |

| Inside a tank | 370x250x250(23L) | 500x300x250(35L) | 370x250x250(23L) | |

| Material | Tank: SUS304 (SUS316L available by special order) | |||

| Weight | 22kg | 39kg | 19kg | |

■Accessories: Lid

●Liquid temperature range: 5 to 100°C

●Transducer: Bolt-clamped Langevin type transducer

●Transducer cable length: 3.5 m

●Optional accessory: Cleaning basket (KG10F, KG11T)

SH Type | Tank type with heater: made to order

| Model | SH06-DX1 | SH12-DX1 | SH06-DX2 | |

| Generator Model No. | WDX-600-I | WDX-1200-I | WDX-600-Ⅱ | |

| Maximum allowable input | 600W | 1200W | 600W | |

| Nominal oscillation frequency | 28kHz、75kHz | 40kHz、120kHz | ||

| Heater | AC200V Single phase 50/60Hz 2kW |

AC200V Single phase 50/60Hz 3kW |

AC200V Single phase 50/60Hz 2kW |

|

| Effective cleaning area | 370×250 | 500x300 | 370×250 | |

| DimensionsWxDxHmm (Excluding protruding parts) |

Externals | 580x310x406 (Including rubber feet) |

710x360x405 (Including rubber feet) |

580x310x406 (Including rubber feet) |

| Inside a tank | 370x250x250(23L) | 500x300x250(35L) | 370x250x250(23L) | |

| Material | Tank: SUS304 (SUS316L available by special order) | |||

| Weight | 28kg | 46kg | 25kg | |

■Accessories: Lid

●Liquid temperature range: 5 to 100°C

●Transducer: Bolt-clamped Langevin type transducer

●Transducer cable length: 3.5 m

●Optional accessory: Cleaning basket (KG10F, KG11T)

*Heater is for water heating only. Please refrain from using it with anything other than water.

*A separate power supply is required to drive the heater.