DESCRIPTION

– Inspects for metal contamination to assure safety and compliance.

– User friendly 7inch touch panel operation

– Multiple frequencies for better detection sensitivity of contaminants, and less false rejection by choosing the most optimizing frequency.

– Available also by only sensorhead.

| Features | |||||

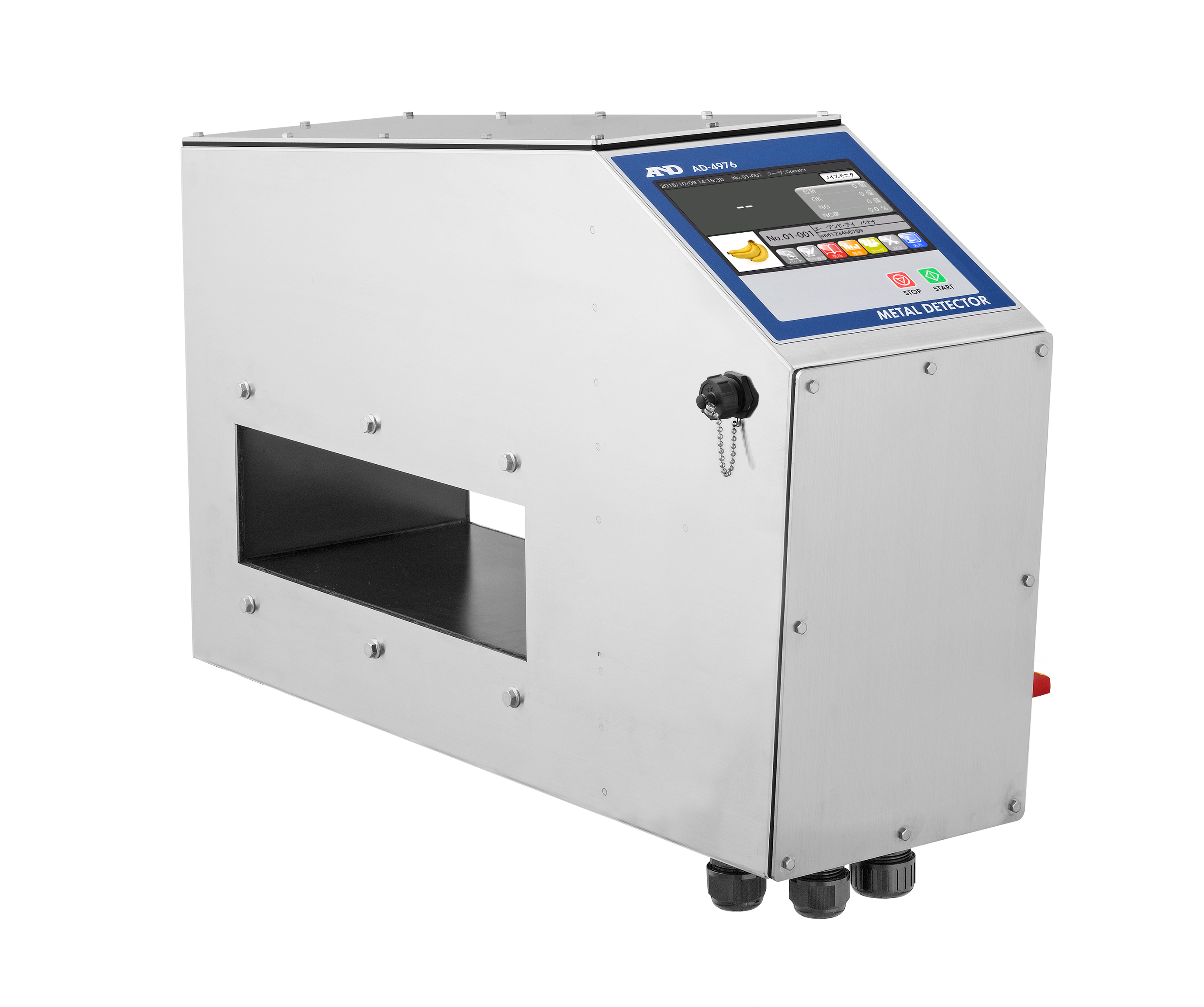

The rugged enclosure is constructed of stainless steel angled surfaces, which is ideal in sanitary reason. Each of these are also separately available for customization to meet various type of requirements. |

|||||

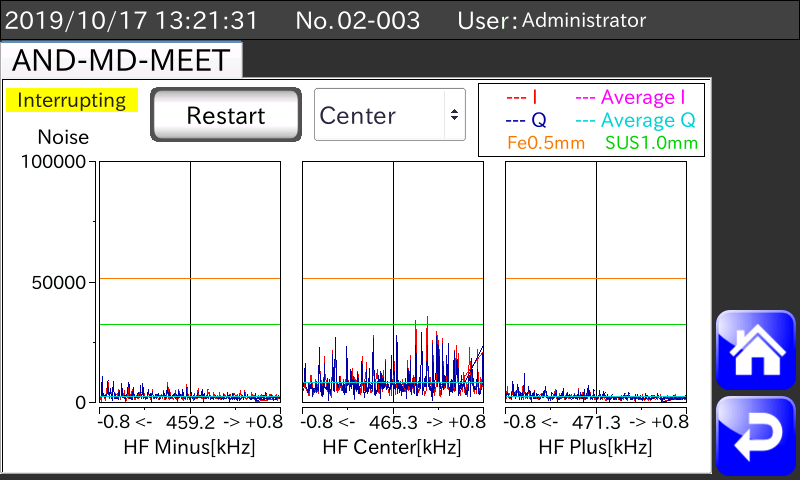

| AND-MD-MEET | |||||

| AND Metal Detector Measurement Environment Evaluation Tool provides stable measurement by visualizing noises around the metal detector with a frequency range set by “Auto” set in its display, and by selecting the best frequency to avoid false detection and unstable inspection. This is powerful tool when unknown cause such as randomly activating inverter is disturbing the metal detector resulting in bad performance or false detection. | |||||

|

|||||

| Modular design | |||||

| AD-4976 consists of three modules: sensor head, conveyor, and frame unit. Each of these are also separately available for customization to meet various type of requirements. As a factory option, the sensor head is available in 90 degrees rotated position so that a tall product can be inspected. | |||||

|

|||||

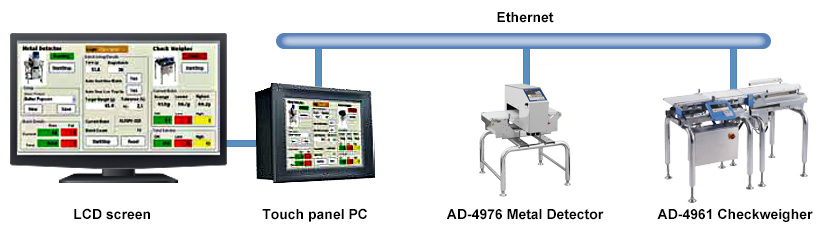

| Modbus communication | |||||

| Equipped with Modbus RTU/Modbus TCP as standard. With Modbus communication, seamless connection can be easily achieved. Operations such as stopping and starting weighing, collecting data and changing product can all be set from an external device. | |||||

|

|||||