Overview

Conveyance facilities that use chain conveyors are widely used in various industries such as iron and steel making and the automobile industry to streamline and save labor in manufacturing, and are playing an even more important role.

This chain grease feeder uses factory air during chain conveyor operation to automatically perform greasing. Greasing is performed reliably thanks to a proprietary mechanism that moves perfectly in parallel and tracks chain movement to ensure that the chain conveyor is most efficiently operated.

Also, a proprietary control system and breakage prevention mechanism during chain reversal enabled a higher-speed greasing than ever before and automatic greasing can be performed in response to conveyor operating conditions.

Features

• Labor Savings and Prevention of Hazardous Work

Automatic lubrication can be easily and reliably performed as this feeder is driven by factory air and conveyor moving force. This both saves personnel expenses, and prevents hazardous work and missed lubrication.

• Extended Service Life of Facilities, Reduced Drive Power

Ideal lubrication is possible. This means that not only can malfunctions due to wear, etc. be prevented and the operating rate of facilities be improved, but also labor costs can also be saved.

• Improved Work Efficiency

Work efficiency can be improved as noise and jerking due to defective lubrication is eliminated and conveyors can be operated at high speed.

• Effective Utilization of Lubricant

This feeder has a mechanism for adjusting the grease quantity. Lubricant can be economically used as greasing can be performed appropriately in this way.

Specifications

| Air supply pressure | 0.4 to 0.5 MPa |

| Lubricant supply pressure | 5 to 15 MPa |

| Air consumption | 1 Nr/cycle (at 0.4 MPa) |

| Lubricant discharge quantity | 0.3 to 2.5 cm3/stroke |

| Lubricant adjustment amount | 0.15 cm3/turn (of adjusting screw) |

| Lubricant used | NLGI consistency No.0 to No.1 grease |

| Ambient temperature | 5 to 60°C |

| CS-120 | CS-220 | CS-222 | CS-223 | |

| Conveyor horizontal run-out tolerance (mm) | ±6 | ±6 | ±10 | ±10 |

| Conveyor vertical run-out tolerance (mm) | ±4 | ±4 | ±4 | ±4 |

| Guide diameter (mm) | 30 to 70 | 30 to 70 | 80 to 140 | 120 to 180 |

| Weight (kg) | 22 | 24 | 24 | 24 |

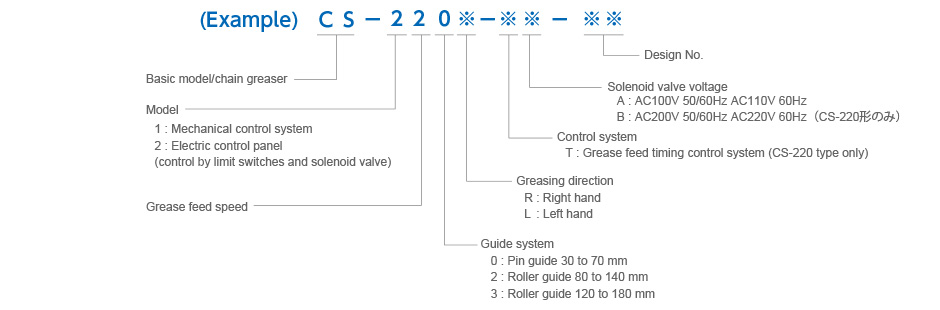

Explanation of Model Symbols