Specifications

| Cooling scheme | Water-cooling type |

|---|---|

| Control models | Temperature and humidity control |

| Cooling capacity(W) | 7000/8000 |

| Thermal capacity(W) | 9700/10700 |

| Humidity capacity(g/㎏(DA)) | 4.04 |

| Temperature stability(℃) | ±0.1 |

| Humidity stability(%RH) | ±0.5 |

| Use Area Temperature(℃) | 15 to 35 (Temperature change gradient: Within 1℃/1h) |

| Use Area Humidity(%RH) | 15 to 85 (Humidity change gradient: within 5%RH/1h) (No condensation) |

| Processed air volume(m3/min) | 20/23 |

| External Dimensions(mm) | H1831×W650×D800 |

| Weight(kg) | 260 |

| Coating Color | Ivory (Y22-85B semi-gloss) |

| Blower duct connection diameter(mm) | φ200 (with damper) |

| Rated voltage(V) | Three-phase AC 200 |

| Consumption Current(A) | 11.5/13.5(Rated) 17(MAX) |

| Consumption wattage(W) | 3200/4200(Rated) 6000(MAX) |

| Humidifier / Water supply pressure(MPa) | 0.2~0.5 |

| Humidifier / Water temperature(℃) | 5~50 |

| Humidifier / Water supply connection port | 15A female socket (Rc: 1/2 inch) |

| Cooling water / Water supply(ℓ/min) | 30 (Amount of change in water volume: within 1ℓ/1h) |

| Cooling water / Water supply pressure(MPa) | 0.2~0.5 |

| Cooling water / Supply water temperature(℃) | 5~35 (Change of water temperature: within 1℃/1h) |

| Drain connection diameter | 20A female socket (Rp: 3/4 inch) |

| Refrigerant(g) | R407C 1500g |

| Safety circuit / Main circuit | Earth leakage breaker (20A 30mA), reverse rotation prevention relay |

| Safety circuit / Blower | Overcurrent relay, delay timer (3 minutes), surge absorber |

| Safety circuit / Compressor | High and low pressure abnormal pressure protection, overcurrent relay, motor protector (140℃ OFF 61℃ ON), surge absorber, cooling water freeze protection, cooler freeze/superheat protection |

*1 Performance value is taken at a point 4 m ahead of the insulation duct. (Ambient temperature and humidity of 25℃ 50%RH and cooling water temperature of 15℃ at 30 ℓ/min)

*2 The temperature and humidity control accuracy is based on the method prescribed in JTMK01 Constant Temperature Humidistat Bath – Performance Testing Method and Performance Display Method (Japan Testing Machine Association). Thermal interference due to ducts etc. is not covered by the precision guarantee. Consider the combined use of insulation ducts etc.

*3 Control may not be possible depending on the ambient temperature and humidity. Discuss the details with our sales representative.

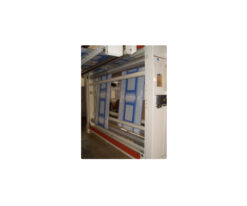

External dimensions

(1) Cooling water outlet

(2) Cooling water inlet

(3) Drain drain port

(4) Overflow drain

Temperature and humidity sensor

(1) Water supply port for humidification

(2) Cooling water inlet

(3) Cooling water outlet

(3) Drain drain port

(4) Overflow drain